Lignatherm Wood Fibre Insulation Board

Lignatherm Wood Fibre Insulation Board

A good choice

Ideal for people and the environment

A good choice

Ideal for people and the environment

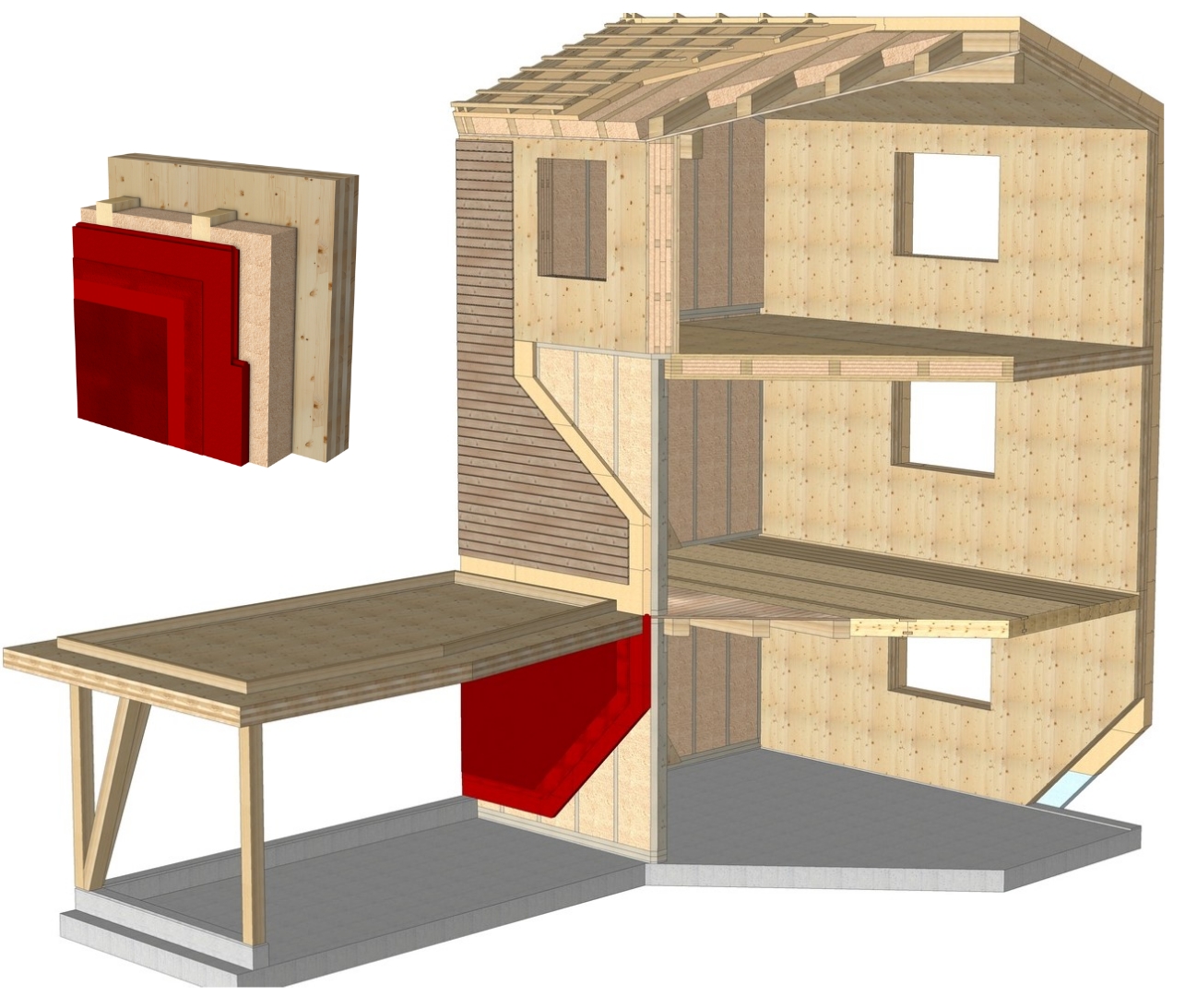

Lignatherm 140/180

The multifunctional panel for roofs, walls and interior fittings

| Density [kg/m3] | 140 | 180 |

|---|---|---|

| Declared thermal conductivity λD [W/m·K] | 0.040 | 0.043 |

| Vapour diffusion µ | 3 | 3 |

| Fire behaviour acc. to EN 13501 | E | E |

| Compressive strength at 10% deformation [kPa] | 100 | 150 |

| Tensile strength perpendicular to board plane [kPa] | 20 | 25 |

| Specific heat capacity [J/kg· K] | 2100 | 2100 |

| Designation | WF-EN13171-T5-DS(70,-)2-CS(10Y) 100-TR20-WS1.0-MU3-AFr100 |

WF-EN13171-T5-DS(70,-)2-CS(10Y) 150-TR25-WS1.0-MU3-AFr100 |

| Thickness [mm] | Length net [mm] | Width net [mm] | Number / pallet [pcs] | Area/ Pallet [m²] | Weight / pallet [kg] | Pallet height [mm] |

|---|---|---|---|---|---|---|

| 60 | 2’531 | 586 | 40 | 59.3 | 540 | 1320 |

| 40 | 1’861 | 586 | 60 | 65.4 | 400 | 1320 |

| 60 | 1’861 | 586 | 40 | 43.6 | 400 | 1320 |

| 80 | 1’861 | 586 | 30 | 32.7 | 400 | 1320 |

| 100 | 1’861 | 586 | 24 | 26.2 | 400 | 1320 |

| 120 | 1’861 | 586 | 20 | 21.8 | 400 | 1320 |

| 140 | 1’861 | 586 | 16 | 17.4 | 375 | 1240 |

| 160 | 1’861 | 586 | 14 | 15.3 | 375 | 1240 |

| 180 | 1’861 | 586 | 12 | 13.1 | 365 | 1200 |

| 200 | 1’861 | 586 | 12 | 13.1 | 400 | 1320 |

| Thickness [mm] | Length net [mm] | Width net [mm] | Number / pallet [pcs] | Area/ Pallet [m²] | Weight / pallet [kg] | Pallet height [mm] |

|---|---|---|---|---|---|---|

| 35 | 2’531 | 586 | 68 | 100.9 | 685 | 1310 |

| 40 | 2’531 | 586 | 60 | 89 | 685 | 1320 |

| 60 | 2’531 | 586 | 40 | 59.3 | 685 | 1320 |

Lignatherm 140/180

The multifunctional panel for roofs, walls and interior fittings

| Density [kg/m3] | Declared thermal conductivity λD [W/m·K] | Vapour diffusion µ | Fire behaviour acc. to EN 13501 | Compressive strength at 10% deformation [kPa] | Tensile strength perpendicular to board plane [kPa] | Specific heat capacity [J/kg· K] | Designation |

|---|---|---|---|---|---|---|---|

| 140 | 0.040 | 3 | E | 100 | 20 | 2100 | WF-EN13171-T5-DS(70,-)2-CS(10Y) 100-TR20-WS1.0-MU3-AFr100 |

| 180 | 0.043 | 3 | E | 150 | 25 | 2100 | WF-EN13171-T5-DS(70,-)2-CS(10Y) 150-TR25-WS1.0-MU3-AFr100 |

| Thickness [mm] | Length net [mm] | Width net [mm] | Number / pallet [pcs] | Area / Pallet [m²] | Weight / pallet [kg] | Pallet height [mm] |

|---|---|---|---|---|---|---|

| 60 | 2’531 | 586 | 40 | 59.3 | 540 | 1320 |

| 40 | 1’861 | 586 | 60 | 65.4 | 400 | 1320 |

| 60 | 1’861 | 586 | 40 | 43.6 | 400 | 1320 |

| 80 | 1’861 | 586 | 30 | 32.7 | 400 | 1320 |

| 100 | 1’861 | 586 | 24 | 26.2 | 400 | 1320 |

| 120 | 1’861 | 586 | 20 | 21.8 | 400 | 1320 |

| 140 | 1’861 | 586 | 16 | 17.4 | 375 | 1240 |

| 160 | 1’861 | 586 | 14 | 15.3 | 375 | 1240 |

| 180 | 1’861 | 586 | 12 | 13.1 | 365 | 1200 |

| 200 | 1’861 | 586 | 12 | 13.1 | 400 | 1320 |

| Thickness [mm] | Length net [mm] | Width net [mm] | Number / pallet [pcs] | Area/ Pallet [m²] | Weight / pallet [kg] | Pallet height[mm] |

|---|---|---|---|---|---|---|

| 35 | 2’531 | 586 | 68 | 100.9 | 685 | 1310 |

| 40 | 2’531 | 586 | 60 | 89 | 685 | 1320 |

| 60 | 2’531 | 586 | 40 | 59.3 | 685 | 1320 |

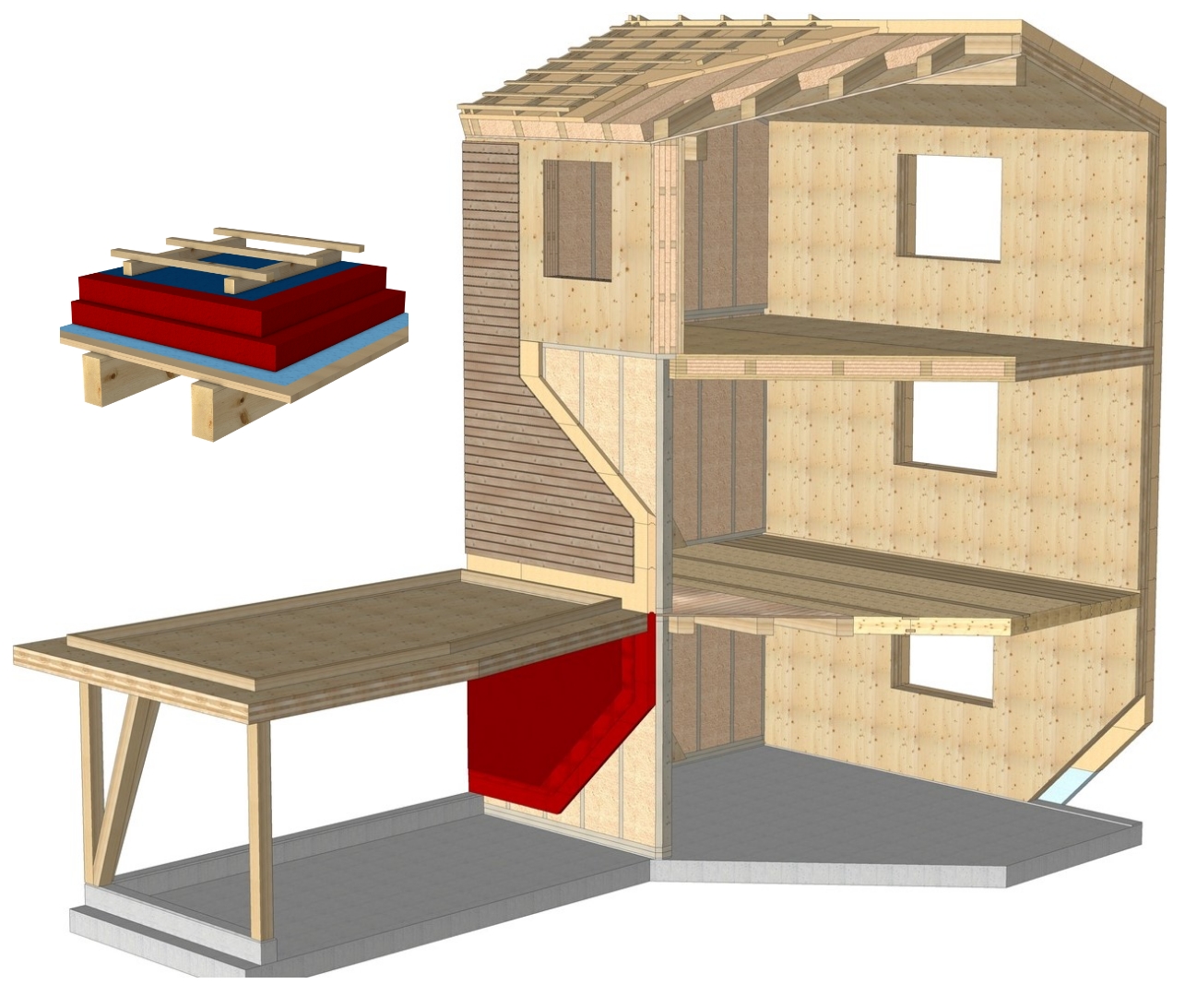

Lignatherm 110

The ideal over-rafter insulation

| Density [kg/m3] | 110 |

|---|---|

| Declared thermal conductivity λD [W/m·K] | 0.038 |

| Vapour diffusion µ | 3 |

| Fire behaviour acc. to EN 13501 | E |

| Compressive strength at 10% deformation [kPa] | 50 |

| Tensile strength perpendicular to board plane [kPa] | 5 |

| Specific heat capacity [J/kg·K] | 2100 |

| Designation | WF-EN13171-T4-CS(10Y)50-TR2.5-WS2.0-MU3-AFr30 |

| Thickness [mm] | Length net [mm] | Width net [mm] | Number / pallet [pcs] | Area/ Pallet [m²] | Weight / pallet [kg] | Pallet height [mm] |

|---|---|---|---|---|---|---|

| 40 | 1’320 | 600 | 120 | 95.0 | 445 | 1’320 |

| 60 | 1’320 | 600 | 80 | 63.4 | 445 | 1’320 |

| 80 | 1’320 | 600 | 60 | 47.5 | 445 | 1’320 |

| 100 | 1’320 | 600 | 48 | 38.0 | 445 | 1’320 |

| 120 | 1’320 | 600 | 40 | 31.7 | 445 | 1’320 |

| 140 | 1’305 | 585 | 32 | 24.4 | 415 | 1’240 |

| 160 | 1’305 | 585 | 28 | 21.4 | 415 | 1’240 |

| 180 | 1’305 | 585 | 24 | 18.3 | 400 | 1’200 |

| 200 | 1’305 | 585 | 24 | 18.3 | 445 | 1’320 |

| 220 | 1’305 | 585 | 20 | 15.3 | 410 | 1’220 |

| 240 | 1’305 | 585 | 20 | 15.3 | 445 | 1’320 |

Lignatherm 110

The ideal over-rafter insulation

| Density [kg/m3] | Declared thermal conductivity λD [W/m·K] | Vapour diffusion µ | Fire behaviour acc. to EN 13501 | Compressive strength at 10% deformation [kPa] | Tensile strength perpendicular to board plane [kPa] | Specific heat capacity [J/kg· K] | Designation |

|---|---|---|---|---|---|---|---|

| 110 | 0.038 | 3 | E | 50 | 5 | 2100 | WF-EN13171-T4-CS(10Y)50-TR2.5-WS2.0-MU3-AFr30 |

| Thickness [mm] | Length net [mm] | Width net [mm] | Number / pallet [pcs] | Area/ Pallet [m²] | Weight / pallet [kg] | Pallet height [mm] |

|---|---|---|---|---|---|---|

| 40 | 1’320 | 600 | 120 | 95.0 | 445 | 1’320 |

| 60 | 1’320 | 600 | 80 | 63.4 | 445 | 1’320 |

| 80 | 1’320 | 600 | 60 | 47.5 | 445 | 1’320 |

| 100 | 1’320 | 600 | 48 | 38.0 | 445 | 1’320 |

| 120 | 1’320 | 600 | 40 | 31.7 | 445 | 1’320 |

| 140 | 1’305 | 585 | 32 | 24.4 | 415 | 1’240 |

| 160 | 1’305 | 585 | 28 | 21.4 | 415 | 1’240 |

| 180 | 1’305 | 585 | 24 | 18.3 | 400 | 1’200 |

| 200 | 1’305 | 585 | 24 | 18.3 | 445 | 1’320 |

| 220 | 1’305 | 585 | 20 | 15.3 | 410 | 1’220 |

| 240 | 1’305 | 585 | 20 | 15.3 | 445 | 1’320 |

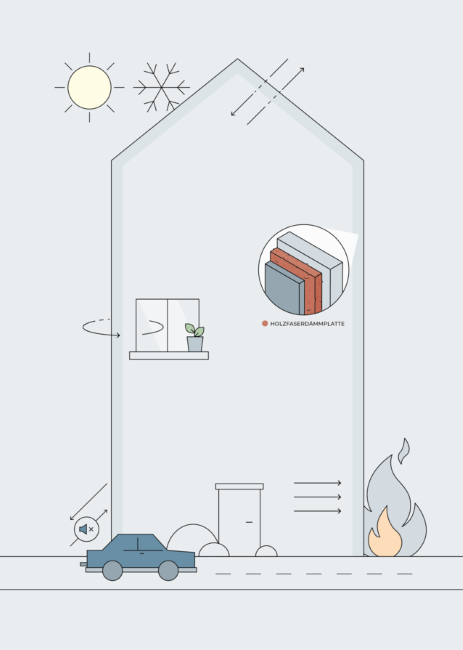

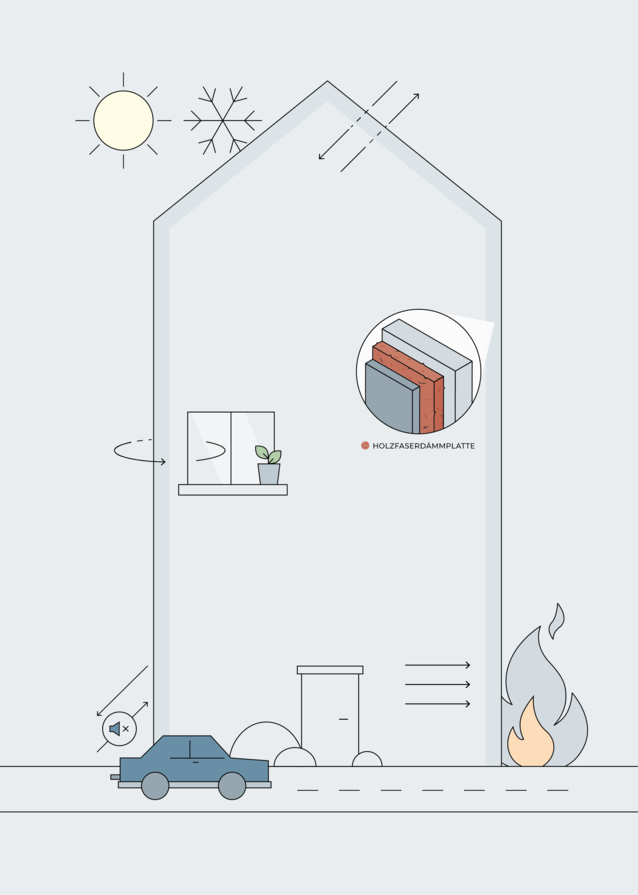

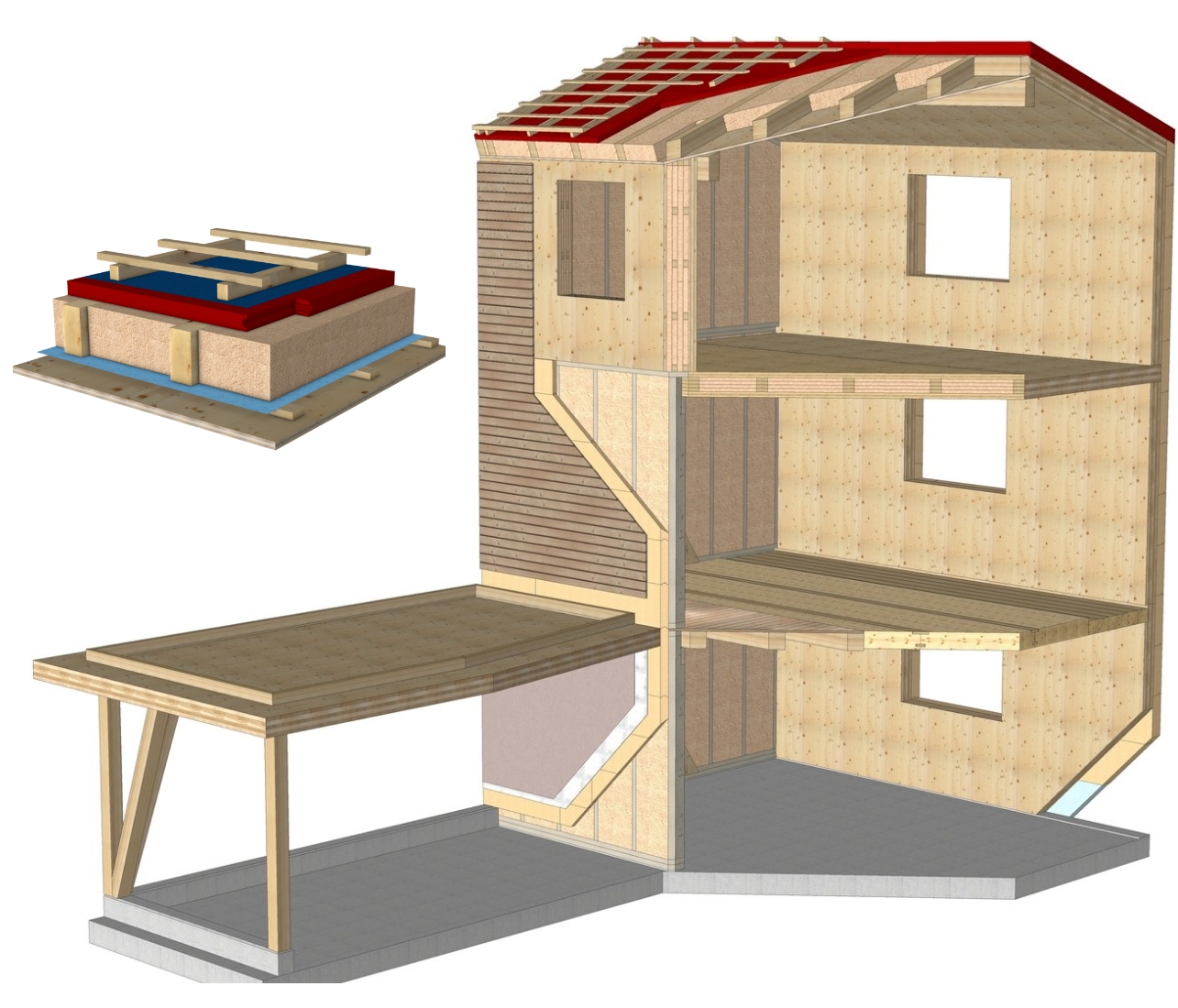

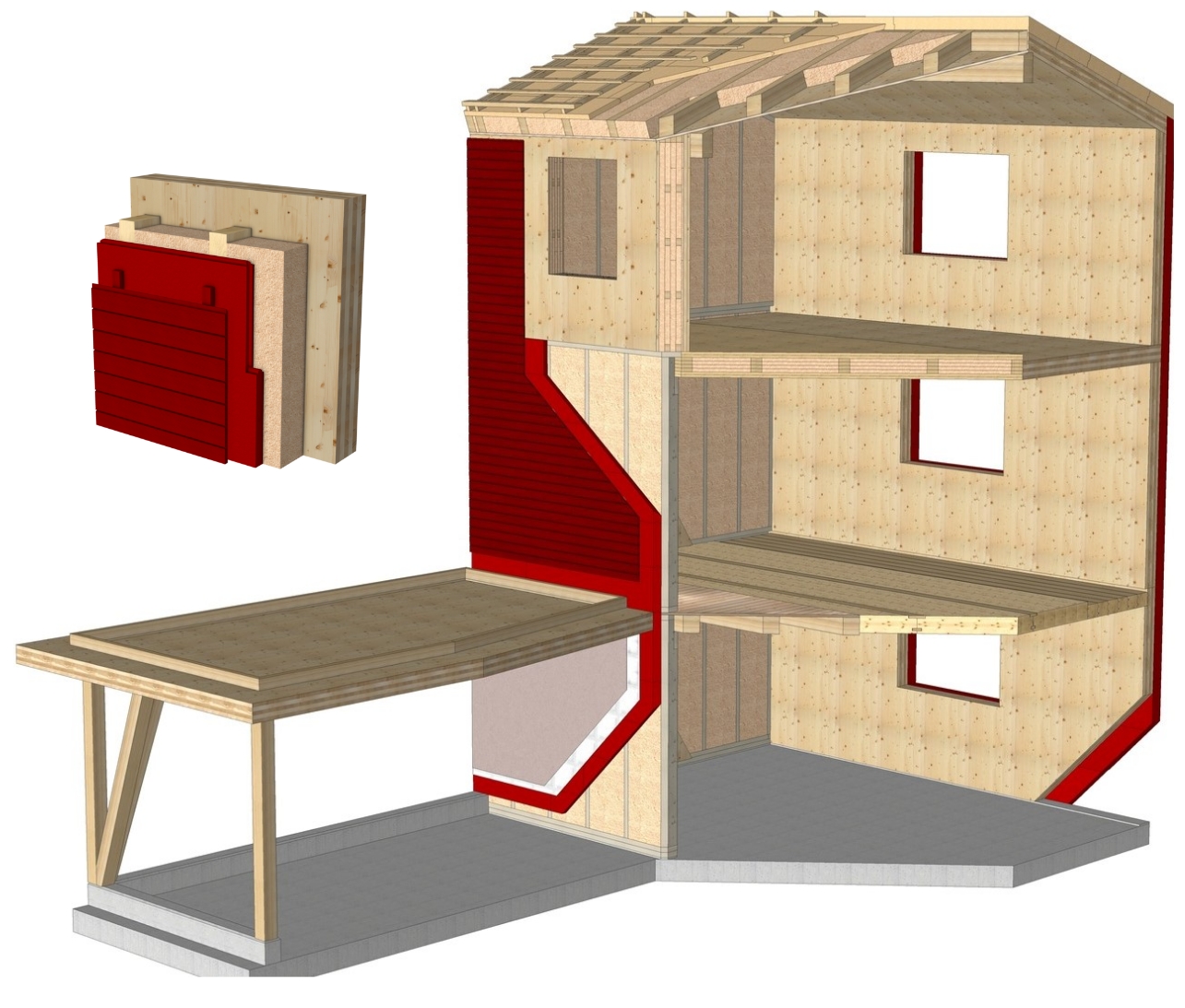

How Lignatherm is used

Your advantages in brief

SWISS QUALITY FROM SWISS PRODUCTION

Schilliger Lignatherm wood fibre insulation boards significantly increase the proportion of Swiss wood in your construction project.

OUR RAW MATERIAL, OUR PRODUCT

The base material for Lignatherm products is wood chips, a by-product from our sawmills. This eliminates the need for costly raw material purchases and keeps transport routes short

EVERYTHING FROM A SINGLE SOURCE

Comprehensive wood products for your entire construction project — lumber, insulation and siding — all sourced from a single provider and delivered directly to your building site

STREAMLINED PRODUCT RANGE

We offer a carefully curated range of products to streamline logistics and simplify storage.

Your advantages in brief

SWISS QUALITY FROM SWISS PRODUCTION

Schilliger Lignatherm wood fibre insulation boards significantly increase the proportion of Swiss wood in your construction project.

OUR RAW MATERIAL, OUR PRODUCT

The base material for Lignatherm products is wood chips, a by-product from our sawmills. This eliminates the need for costly raw material purchases and keeps transport routes short

EVERYTHING FROM A SINGLE SOURCE

Comprehensive wood products for your entire construction project — lumber, insulation and siding — all sourced from a single provider and delivered directly to your building site.

STREAMLINED PRODUCT RANGE

We offer a carefully curated range of products to streamline logistics and simplify storage.

Our production – sustainable and efficient

The raw material used is wood chips from Swiss wood, which are produced in the sawmills of Schilliger Holz AG in Haltikon and Perlen, among others, in the immediate vicinity of the new fiber insulation board plant.

The wood fiber insulation boards are produced using state-of-the-art, energy-efficient equipment in a dry process. There are no extraordinary noise emissions. Virtually 100% of the emissions produced during the drying process consist of water vapor. The exhaust air is dust-filtered.